Remblokken:

Alle remblokken zijn sintered behalve de M1 compound!

Here an overview of all different compounds:

| Compounds |

| Most types of brakepads are available in several different compounds, adapted to the use of the brakepad. |

| ATB pads are available in ATB-N material. |

| Explanation of the several compounds |

| Main compound-groups are: N(2), D, CPRO and M. These main compounds are adapted for use in the different brakepad-categories as on-road, off-road, etc. N-compound. DELTA braking standard compound. High friction. No fading. Long lasting. Not aggressive towards the disc. A classical compound in sintered metal friction technology. The N(2) compound has obtained a TÜV Approval. D-compound. DELTA braking heavy duty compound. Where others give up: D goes on! Special in use under extreme circumstances: mud, sand, water. Therefore in use in off-road and quads. High friction, No fading. Extreme long lasting. But more aggressive towards discs! CPRO-compound. A new development by DELTA braking R&D A soft compound containing a high percentage of, specially developed, friction carbon. Extreme high friction. Very high temperature resistant. In use for (semi) road-racing, supermotard, and motocross, but … pay attention: CPRO, being a soft compound, doesn’t like the combination of mud, sand, and water! M–Compound. To complete the DELTA braking production program, we also produce a classical compound of mineral (organic) origin. A complete different technology. No sintering process. Available for older type motorcycles, and for customers, who want more economical brakepads. Also the M-1 compound has a TÜV Approval. |

Remschijven

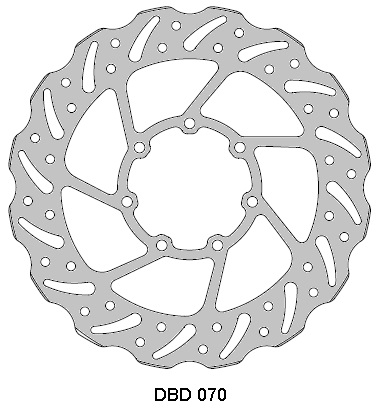

Er zijn van Delta Braking 2 types remschijven, de Type D & Type G

Per model kan de remschijf iets afwijken naar wat er hieronder afgebeeld word

Type G:

Type D:

Voor alle informatie kan u kijken op www.delta-braking.com